Christmas 2025: How to Win The "Intentional" Shopper

The Christmas rush is on for Australian SMB retailers. This year, customers are more fuzzy. This is better for SMB shops.

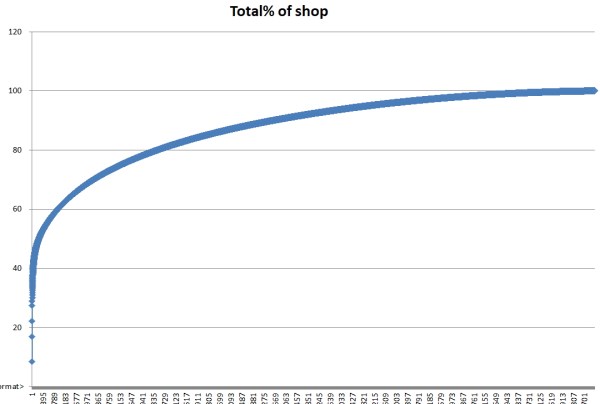

New research from the Australian Retailers Association (ARA) and Roy Morgan indicates that gift-buying participation has slightly decreased by 9%. Shoppers, however, are now spending more and prioritising genuine connection. We call this the "Intentional" Shopper. To them, it's no longer about who has the cheapest plastic gadget, something that an SMB retailer finds hard to compete with.

Who is the "Intentional" Shopper?

We keep hearing this word: "Intentional." But what does it actually mean for your daily trade?

In 2025, Australian shoppers are swapping "loyalty for logic". They aren't just walking into a shop and buying a cheap thing. They are researching first. They have a specific person in mind, a specific budget, and a particular feeling in mind for the gift. Clearly, they want to buy treasures.

The data backs this up. High-spending shoppers aged 35 to 54 are averaging $853 in spend this season. That is a serious amount of money. But they aren't spending it on just anything. They are looking for value, quality, and meaning.

Why This Matters for You

This is great news for independent retailers. You don't have to compete with big-box stores on price-slashing. An intentional shopper walks into your store, looking for you to be the expert. They want you to say, "If your kid loves their dog, she will absolutely adore this dog toy."

That personal advice is something online shops cannot do.

The Return to Physical Media

One of the most encouraging trends for independent retailers this year is the renewed interest in tangible "Recreational Goods," including books.

We are seeing a massive pushback against the digital world. People are tired of screens. They want things they can hold, smell, and keep. This has driven a surge in demand for:

- Physical Books: Hardcovers are having a huge moment.

- Stationery: Beautiful journals and pens are top gifts.

- Leisure Items: Puzzles, board games, and craft kits.

The data suggests that these high-spending 35-54-year-olds are driving this demand. They want gifts that offer "genuine value" and an experience.

How to Merchandise for "Touch"

Because these shoppers want tactile experiences, your store needs to be hands-on.

- Open the Box: Don't seal everything. Have a sample journal open so people can feel the paper.

- Create Reading Nooks: If you sell books, stack them so they invite people to pick them up.

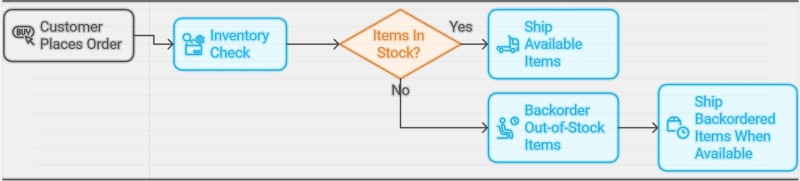

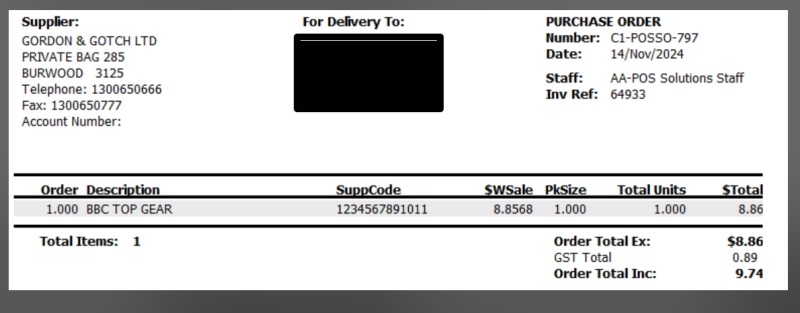

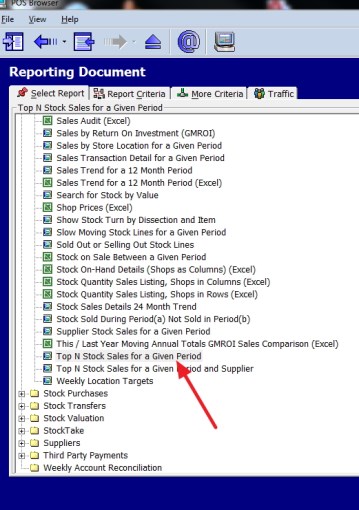

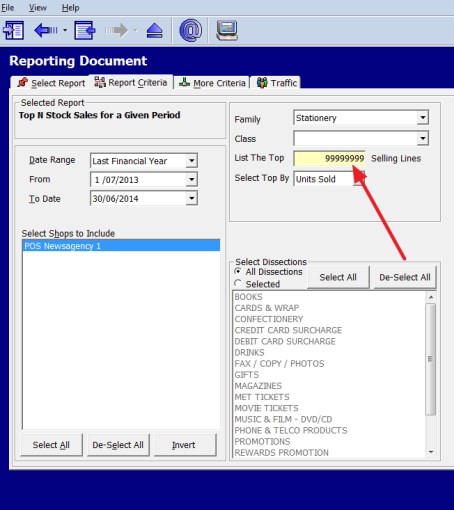

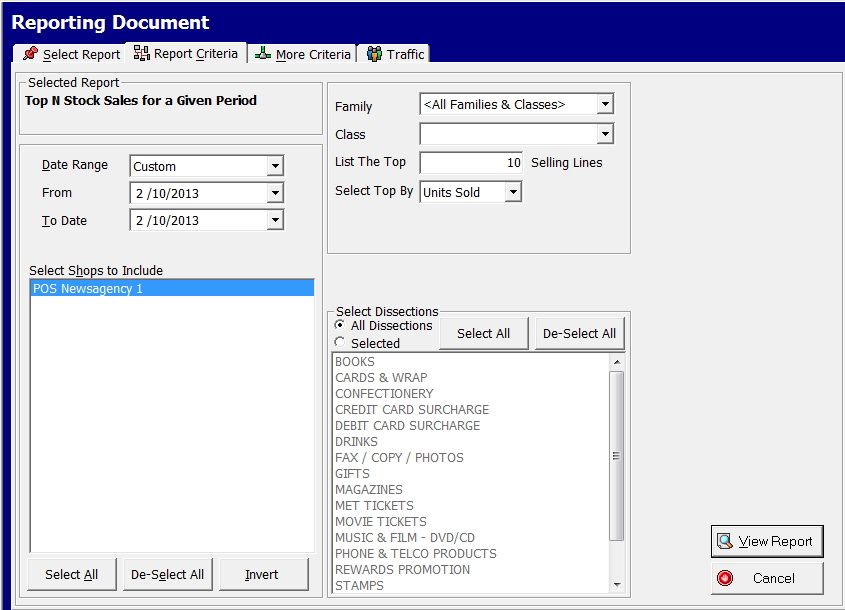

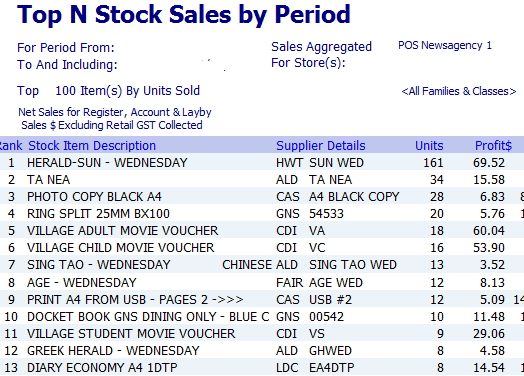

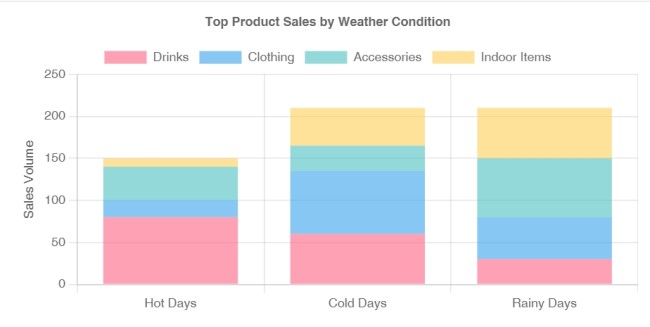

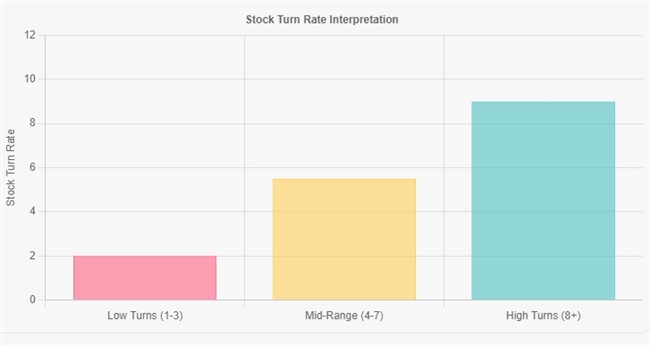

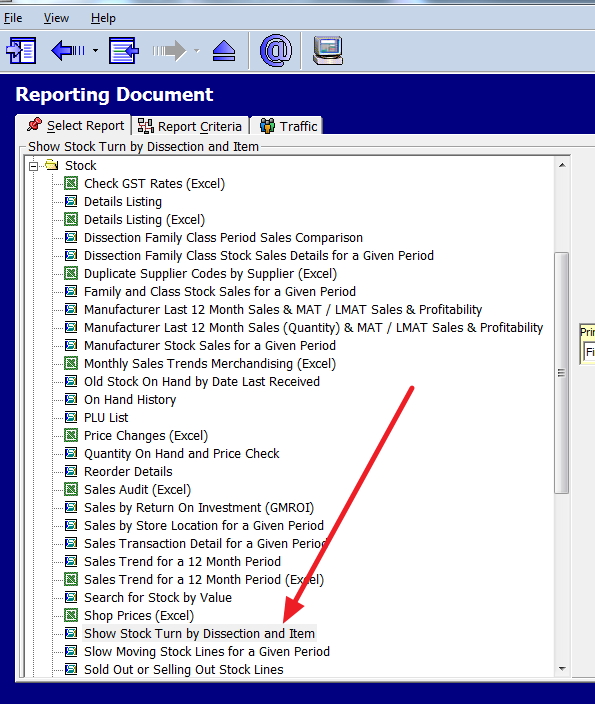

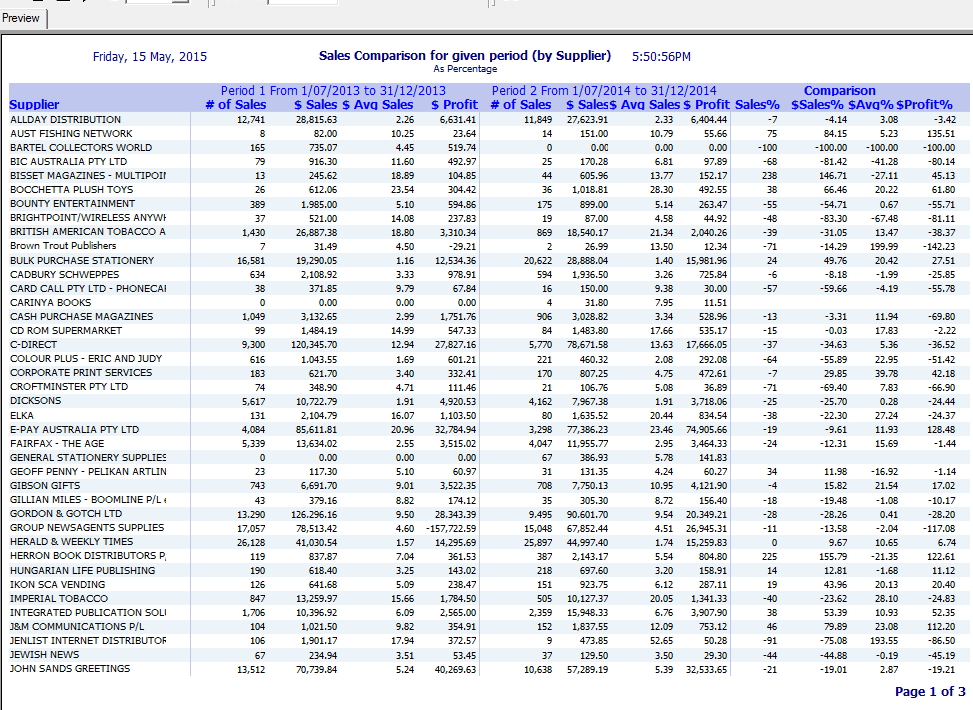

- Bundle It Up: Use your point-of-sale system to see which items are often bought together. If people who buy a specific cookbook often buy a wooden spoon, bundle them together on a display table. This makes the "intentional" choice easy for the customer.

Personal Connection Wins the Sale

This Christmas, consumers are demonstrating a clear preference for personal touches over mere convenience. In a significant market shift, only 22% of Australians say they are making more purchases online than a year ago—less than half the level seen in 2021.

This is a massive retreat from digital-only shopping. It reinforces that consumers are deliberately choosing to visit physical stores. In fact, most Australian consumers prefer shopping in brick-and-mortar stores.

Why? Because they want to find value and Connection.

The "Trust" Factor

As Catherine Jolley of Roy Morgan notes, "In this environment, trust is your most important asset." Shoppers want to see, touch, and trust the product before they purchase. They also want to trust you.

When an intentional customer walks in, they aren't just looking for stock; they are looking for help. This gives you a crucial advantage. You can leverage product knowledge to enhance the look and feel of your gift lines.

Of course, if the intentional shopper might come in for a specific $50 book, but if they see a beautiful $10 bookmark or a $15 candle right next to the register, they are very likely to add it to the basket. We call this "basket building."

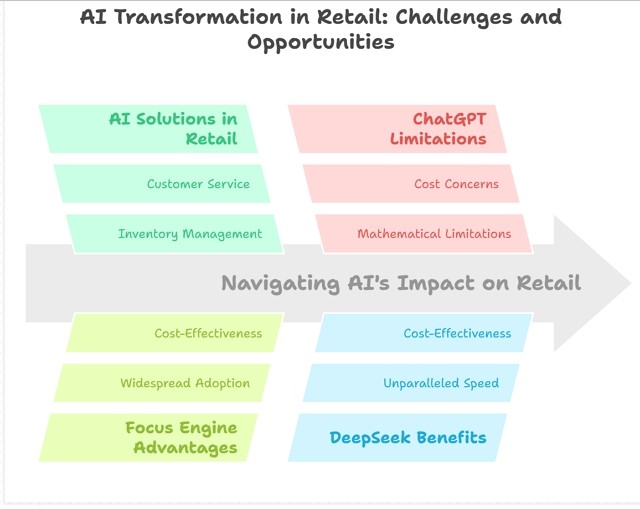

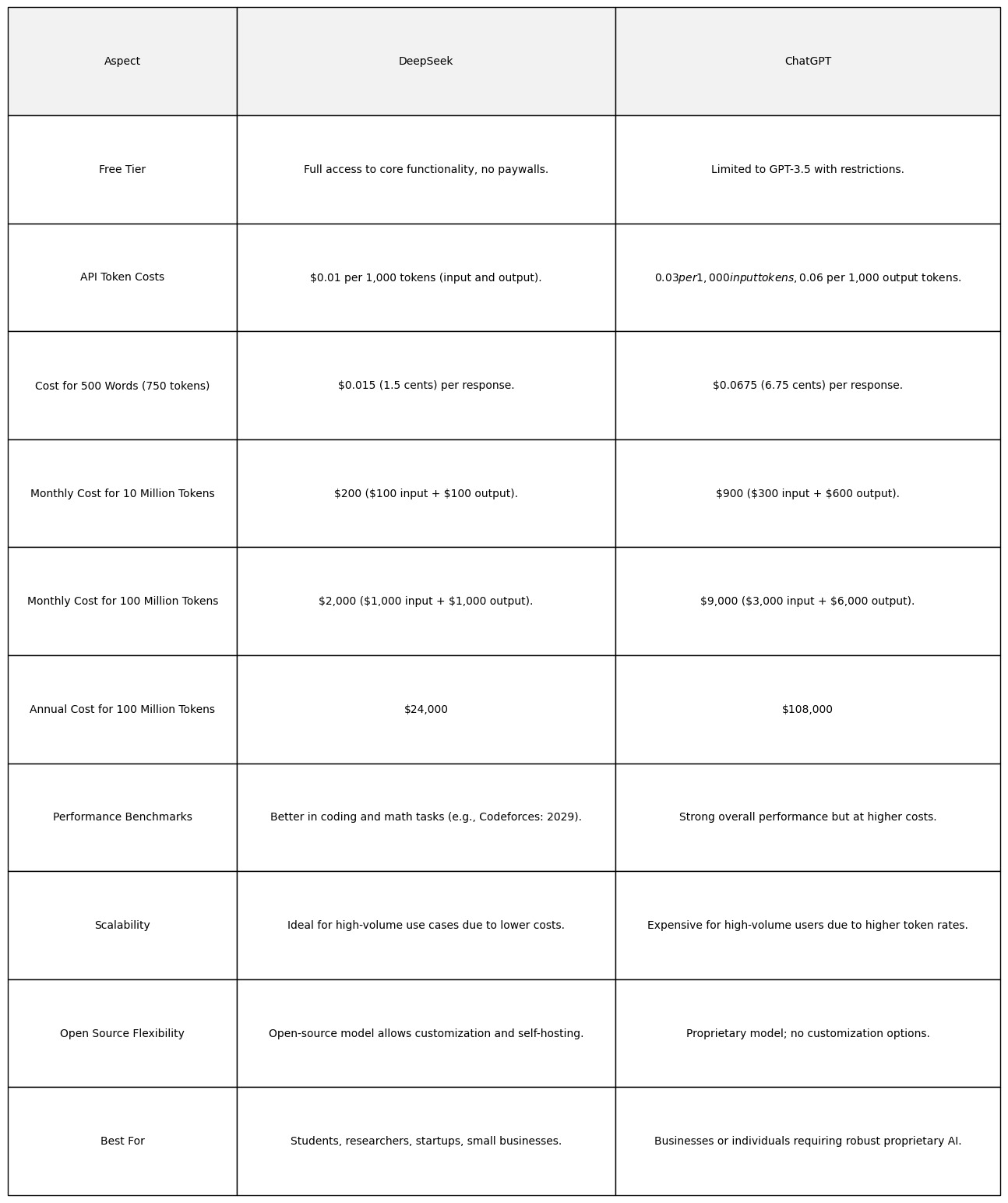

Using Tech to Build Connection

The right technology actually helps you build better human connections.

Those small moments of service are what turn a one-time Christmas shopper into a loyal regular for the whole of 2026.

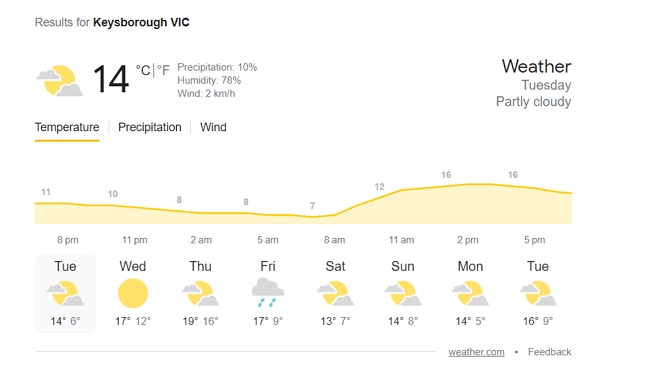

Timing for the Intentional Shopper

The data also highlights the importance of early preparation. Nearly one in three consumers (29%) started their Christmas shopping earlier than in 2024.

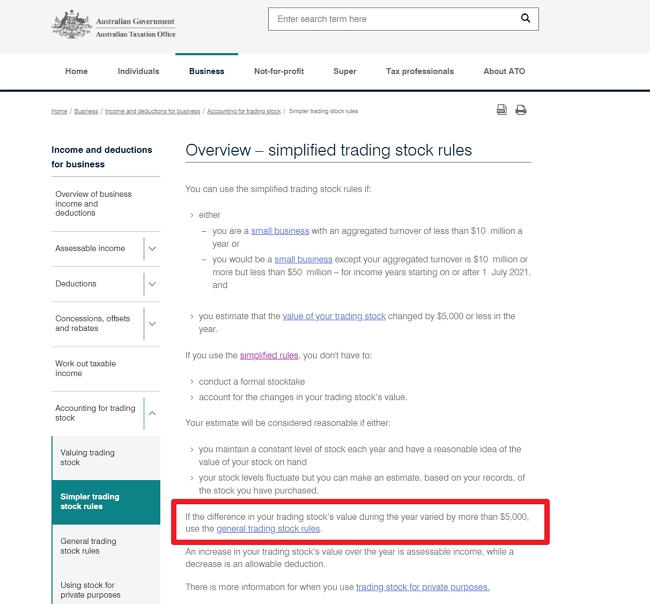

The "Layby" Advantage

I think these shoppers are not just early because they are looking, but also because they are trying to spread their budgets over several pay cycles. It ensures they secure these costly items. I know it's a pain, but consider offering "Layby," which allows customers to secure that expensive, perfect gift now and pay it off over a few weeks.

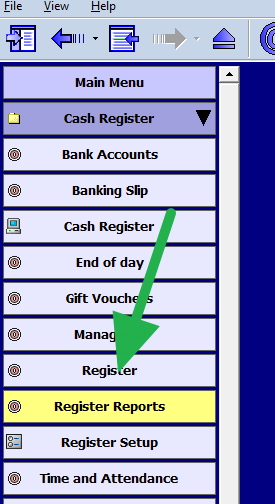

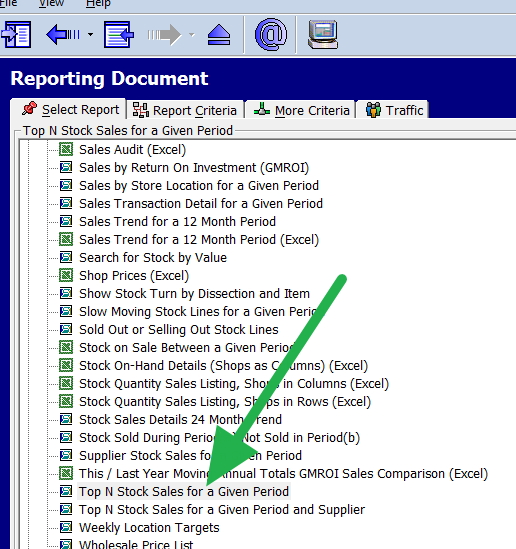

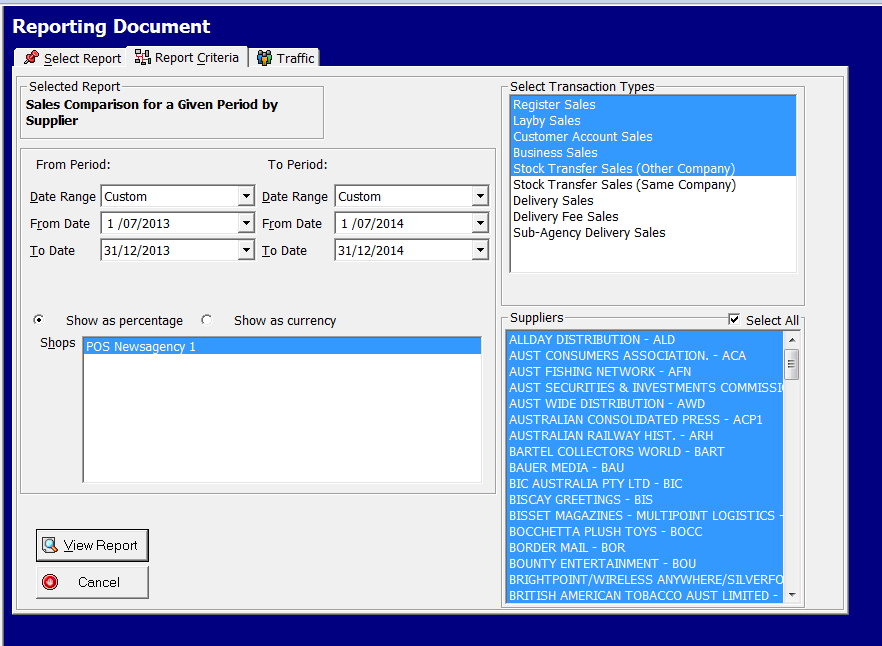

Check Your System: Make sure you know how to use your POS system's Layby feature. It is a one-click process. Your staff need training on the Layby, too, or you might miss out on these high-value sales.

Strategy: The Counter Display

- Low Cost, High Joy: Place small, tactile items near your Point of Sale (POS) system. Things that don't need much thought but bring a spark of joy.

- Gift Add-ons: A sign for your cards, wrapping paper, and ribbons should always be displayed at the checkout.

Is Your Store Ready?

If your store is a mess, these calm, focused shoppers will walk right out. You are trying to sell a premium item