One particularly frustrating issue that often crops up when dealing with stock items is that some items that you do not want keep coming back. These products linger on your shelves, occupying valuable space and tying up your capital. Here is a nifty trick in our software worth looking into: how to blackmark a stock item.

What is Black Marking?

Before diving into the mechanics, let's clarify what "black marking" means. Black marking flags a stock line in your point-of-sale (POS) system as a product you no longer want to receive. It's like putting that item on your "do not order" list.

Why Would You Want to Black Mark an Item?

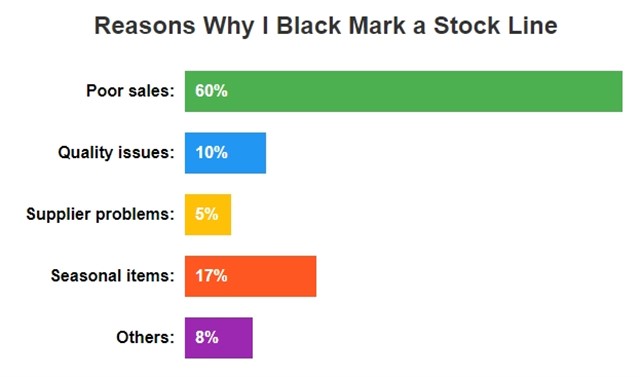

There are several reasons why you might want to blackmark a stock item:

- Poor sales performance: The item needs to move off the shelves.

- Quality issues: You've received so many complaints about the product that you feel bad about stocking it. For example, I now refuse to sell a range of printers. They have great reviews, but they are terrible.

- Supplier problems: Supplier problems are always a problem; there are just some people you want to avoid dealing with.

- Seasonal items: You want to prevent reordering Christmas decorations in July!

How to Black Mark a Stock Item

Here's how you can blackmark an item in your POS system:

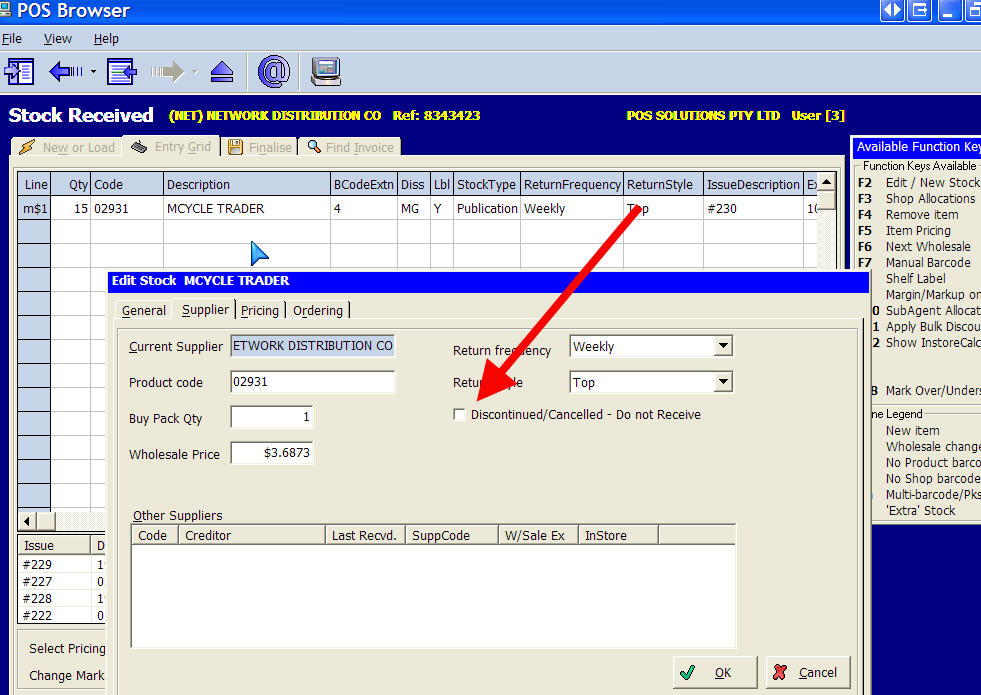

Method 1: During Stock Receiving

- Open your stock receiving screen.

- Press the edit button.

- Look for the column indicated by the red arrow (in your POS system, this will be labelled "Do Not Receive" or something similar).

- Mark the checkbox for the item you want to black mark.

Method 2: In Stock Maintenance

Alternatively, you can black-mark an item directly in your stock maintenance screen:

- Navigate to your stock maintenance section.

- Find the item you want to black mark.

- Look for a "Do Not Receive" or similar option.

- Toggle this option on for the item.

What Happens After You Black Mark an Item?

Once you've black-marked an item, a couple of things will happen:

-

No Automatic Ordering: The system will no longer automatically order this product, even if it falls below your usual reorder threshold.

-

Instant Return File: If the item somehow ends up in your receiving list (maybe a colleague ordered it manually), it will be moved to a separate list—often called the "Instant Return File." You can then deal with it promptly, perhaps by returning it to the supplier or finding an alternative solution.

My Personal Experience

I first learned about black marking in my grandfather's shop. Grandfather was so happy when he finally sold a stock line. Mum was doing an order, seeing we were out of it, and ordered some more. Soon, every time Grandfather turned around, he said that these products were mocking him from the shelves.

Best Practices for Black Marking

While black marking can be a powerful tool, it's essential to use it wisely. Here are some tips:

- Regular Review: Periodically review your inventory list. The problem with computers is once you do something, it is there forever. Yet market trends change, and a product that did not sell last year might be the next big thing this year.

Communication: Ensure your team understands what black marking means and how to do it.

- Data-Driven Decisions: Don't black mark items on a whim. Use your sales data to decide which products to blackmark.

Conclusion

Black marking for stock items is a simple yet powerful method to enhance inventory management. It prevents the gathering of unsold stock, liberates capital, and enables you to prioritise products that foster business growth. Remember, staying ahead in inventory management is crucial, and black marking gives you that edge. I encourage you to experiment with it as you will find it as helpful as I have over the years.

Happy retailing!

FAQ: Black Marking Stock Items in Retail

Q: What is black marking?

A: Black marking is a process in your point-of-sale (POS) system where you flag a stock item as one you no longer want to receive or reorder. It creates a "do not order" list for specific products.

Q: Why would I want to blackmark an item?

A: You might want to blackmark an item for several reasons:

- Poor sales performance

- Quality issues with the product

- Problems with the supplier

- Seasonal items you don't want to reorder out of season

Q: How do I blackmark an item in my POS system?

A: There are typically two methods:

-

During stock receiving:

- Open the stock receiving screen

- Press edit

- Find the "Do Not Receive" column

- Mark the checkbox for the item

-

In-stock maintenance:

- Navigate to stock maintenance

- Find the item

- Look for a "Do Not Receive" option

- Toggle it on

Q: What happens after I blackmark an item?

A: Two main things occur:

- The system won't automatically reorder the item

- If the item appears in your receiving list, it'll be moved to an "Instant Return File" for you to deal with promptly

Q: Can I undo a black mark?

A: Yes, you can typically undo a black mark by following the same process you used to mark it and unchecking the "Do Not Receive" option.

Q: Should I review my black-marked items?

A: It's a good practice to review your black-marked items periodically. Market trends change, and a previously unpopular item might become in demand.

Q: Will black-marking an item remove it from my inventory?

A: Black marking doesn't remove the item from your inventory. It only prevents future orders of that item.

Q: Can my staff black-mark items?

A: This depends on your POS system's settings and business policies. It's essential to communicate with your team about the black marking process and who has the authority to do it.

Q: Is black marking the same as discontinuing an item?

A: Not necessarily. Black marking prevents reordering, but the item may remain in your inventory. Discontinuing usually involves removing the item from your product list entirely.

Q: How often should I use the black marking feature?

A: Use it as needed, but always base your decision on data and careful consideration. It's a tool to help manage inventory, not a solution for every slow-moving item.