If you are struggling with order fulfilment, look at partial fulfilment.

Understanding Partial Fulfillment

Partial fulfilment is a strategy in which the retailer has backorders from customers; they then ship the available items and bill from an order ASAP while leaving the rest on backorder. This approach offers flexibility in order processing, improving customer satisfaction and cash flow.

How Partial Fulfillment Works

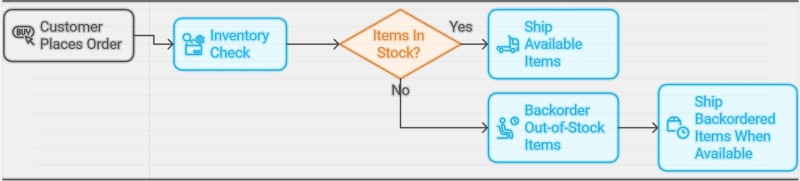

The process is straightforward:

- A customer places an order for multiple items.

- Your inventory system identifies which items are in stock.

- When available, the items are shipped immediately.

- Out-of-stock items remain on backorder to be shipped when available.

So, customers receive a portion of their order now rather than waiting for all items to be in stock before shipping.

The Advantages of Partial Fulfillment

Implementing partial fulfilment brings numerous benefits to your retail business:

Improved Cash Flow

By shipping available items immediately, you can invoice and receive payment sooner.

Enhanced Customer Satisfaction

Customers appreciate receiving part of their order quickly rather than waiting for everything to be in stock.

Reduced Storage Costs

You can operate with leaner inventory levels, reducing warehouse space requirements.

Better Inventory Management

It is easier to keep track of items more effectively.

Multi-Location Stock Management

You can often order directly from the supplier and deliver the goods directly to the customer. Just be careful that the customer needs to get the price. I find this cheaper and more manageable. If they provide it to me anyway, and then I deliver it to the customer, why not have the supplier do it directly? Let them have the headache and cost of delivery.

Increased Flexibility

You can fulfil orders from whichever location has the stock available.

Faster Order Processing

By utilising stock from multiple locations, you can process orders more quickly.

Reduced Shipping Costs

Often, you can ship from the location closest to the customer, minimising shipping expenses. Smart route optimization helps cut costs even further by ensuring deliveries take the fastest and most efficient path.

Implementing Partial fullfilment

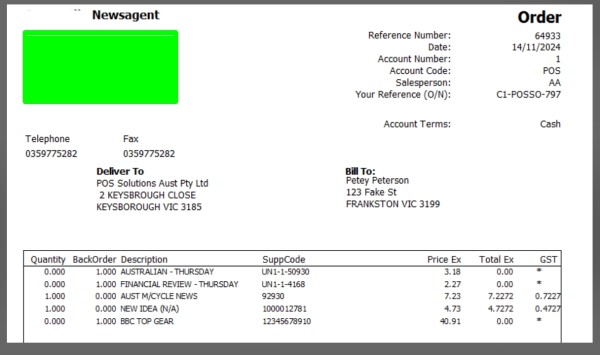

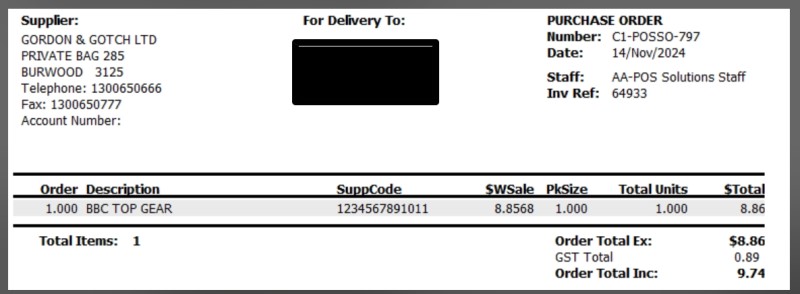

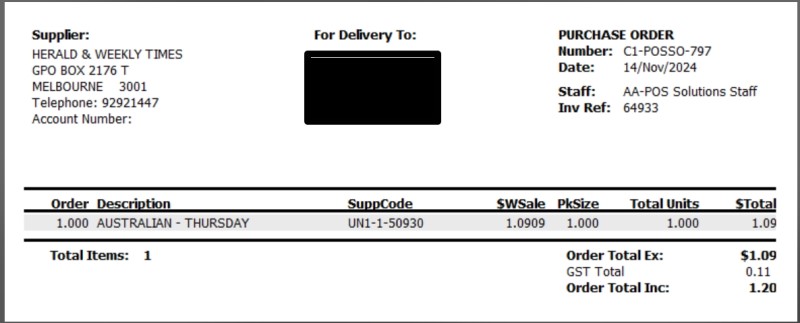

Go to business invoicing.

This is a test example of how it works

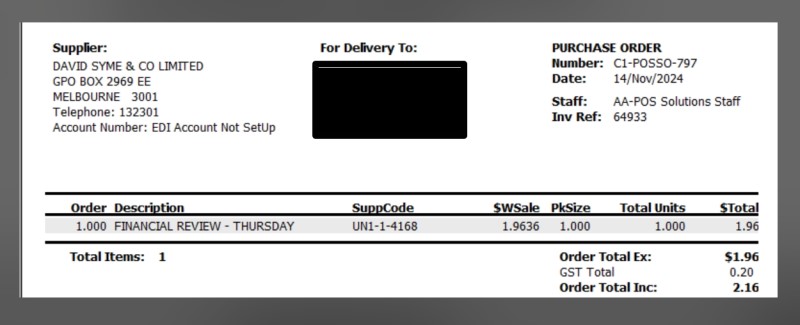

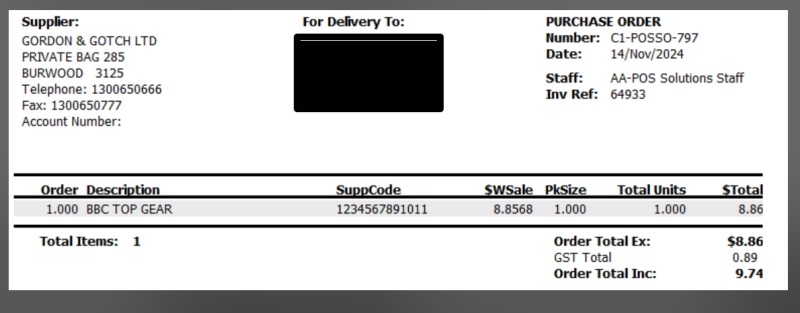

Now, we have four separate orders from suppliers to fulfil the customer's order

Why wait till the last one of these arrived to ship it out?

Train Your Staff

Properly educate your team on handling partial orders.

Overcoming Common Challenges

While implementing these strategies, you may encounter some challenges:

Clear Customer Communication

Be transparent about partial shipments and expected delivery dates for back-ordered items. I would like to include the shipping details so the customer can directly contact the shipper without me having to deal with the middleman's headaches.

Managing Shipping Logistics

You may need to coordinate with multiple carriers or locations. With our POS System and correct processes in place, these challenges can be effectively managed.

Success Stories: Australian Retail Triumphs

Consider these real-world examples of Australian retailers who have successfully implemented these strategies:

- Newsagents doing Back to School Often wait for goods to arrive on the order, but why hold up 90% of the order because 10% has yet to come?

- We do it - We often have to wait for a part, but there is no reason we cannot send out what we have now.

Conclusion

Learning how to do partial fulfilment can transform your retail business. It enables you to maximise inventory, improve customer satisfaction, and boost revenue.

FAQ

Q: What does it mean when an item is back-ordered?

A: A back-ordered item is generally out of stock in the shop, but the supplier can still purchase it with a future delivery date once inventory is replenished. The item will be shipped when it becomes available again, and customers are placing orders for when it arrives.

Q: What is the difference between backorder and out-of-stock?

A: The key differences are:

- Backorders can still be purchased and will be delivered when available

- Out-of-stock items cannot be ordered until they return to inventory

- Backorders have an estimated delivery timeframe

- Out-of-stock items have no guaranteed return date

Q: What is the difference between a backorder and a pre-order?

A: Here are the main distinctions:

- Pre-orders are placed before an item is released or manufactured

- Backorders are placed after an item has been released but is temporarily unavailable

- Pre-orders typically require upfront payment

- Backorders usually charge payment upon shipping

- Pre-orders help gauge initial demand

- Backorders help manage existing demand for established products

Q: How does the partial fulfilment process work?

A: 1. Customer submits an order for multiple items

2. System checks inventory availability

3. Available items are shipped immediately

4. Backordered items are shipped when they become available

Q: Can suppliers ship directly to customers?

A: Suppliers often can ship directly to customers, reducing handling costs and delivery complications.

Q: What do I need to prepare before implementing partial fulfilment?

A: - Train staff on handling partial orders

- Set up proper business invoicing systems

- Establish clear communication protocols

- Implement inventory tracking systems

Q: How do I manage shipping logistics?

A: Coordinate with multiple carriers and locations through your POS System and established processes.

Q: How should I communicate partial shipments to customers?

A: Provide transparent information about:

- Which items are shipping immediately

- Expected delivery dates for back-ordered items

- Shipping tracking details

Q: Will customers accept partial deliveries?

A: Generally, customers prefer receiving some available items quickly rather than waiting for complete orders.

Q: What are the financial benefits?

A: - Improved cash flow from faster billing

- Reduced storage costs

- Lower shipping expenses through optimized delivery routes

- Better inventory turnover

Q: How does it affect inventory management?

A: - Enables leaner inventory levels

- Improves stock tracking

- Allows for multi-location stock management

- Facilitates faster order processing