AI Ordering Reality: Why Smart Retailers Stay in Control

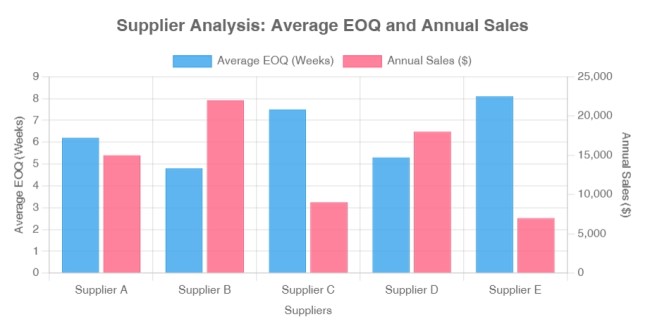

AI-powered automated ordering systems can quickly process thousands of stock lines, but they lack context understanding. While retail demand forecasting algorithms identify sales patterns, they often miss real-world factors crucial for smart decisions in retail environments like newsagencies.

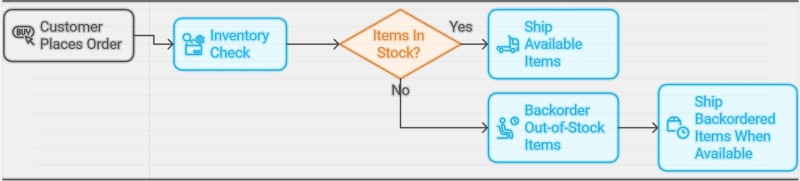

Human-in-the-loop workflows are essential because AI software ensures speed and consistency, but effective stock management depends on recognising whether sales spikes reflect genuine demand or noise.

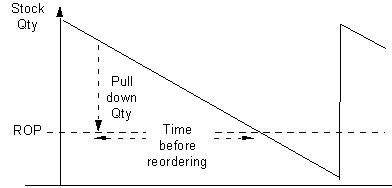

Why AI Inventory Management Needs Human Oversight

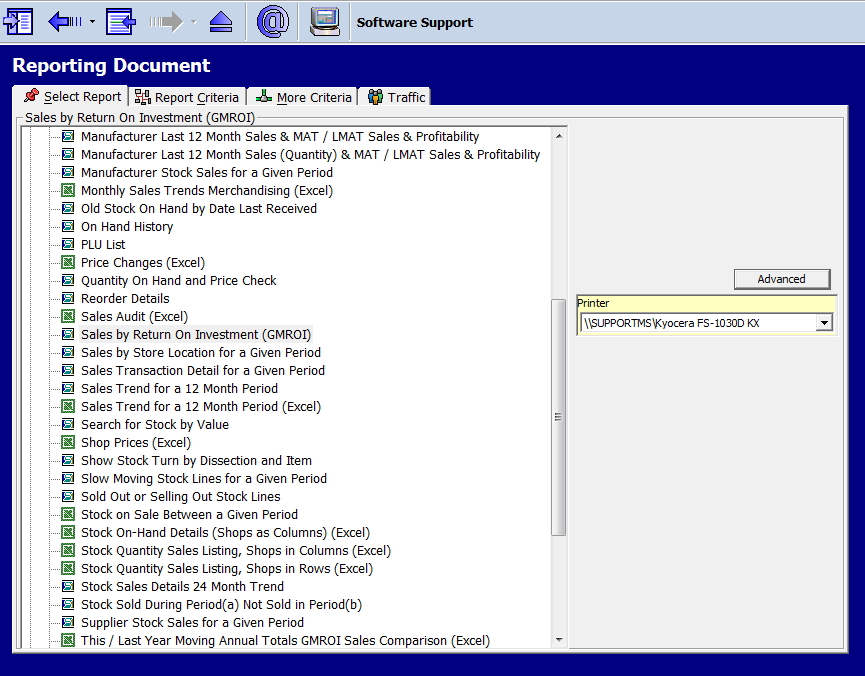

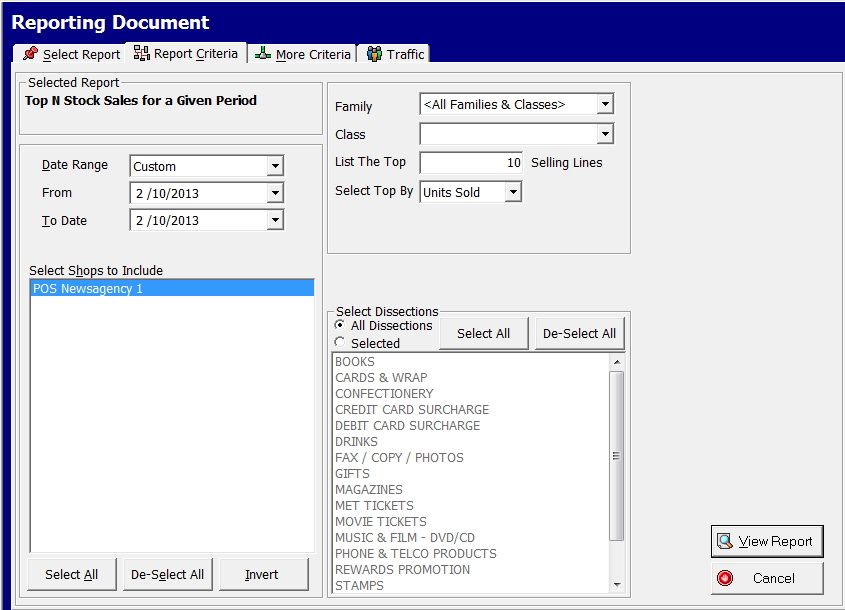

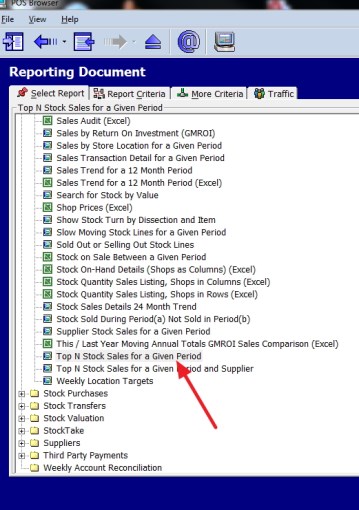

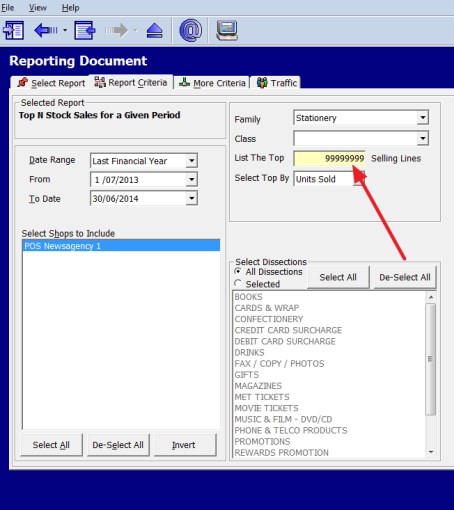

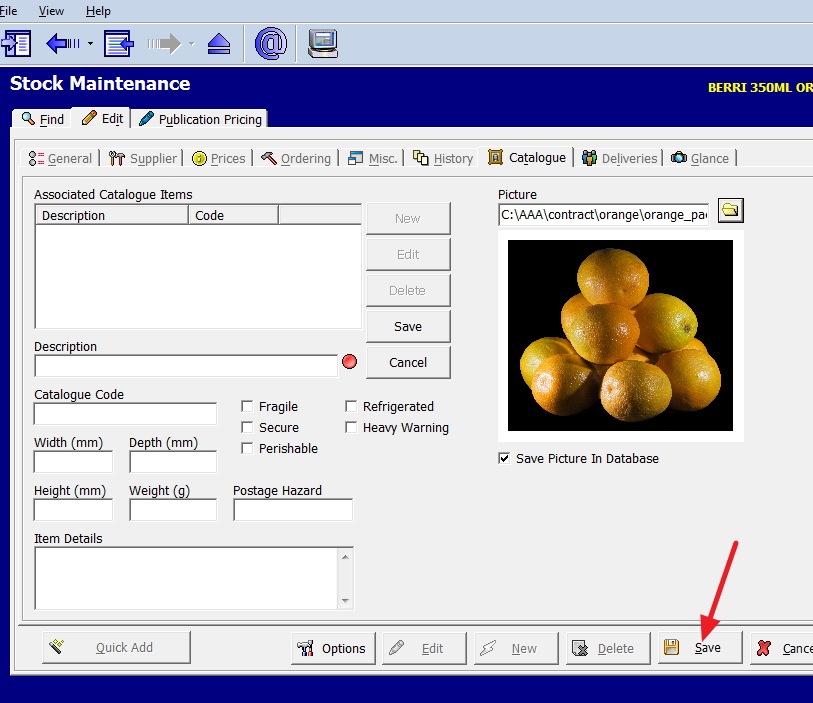

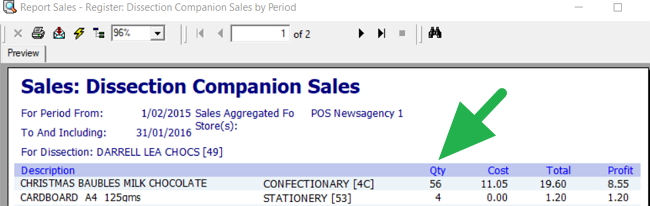

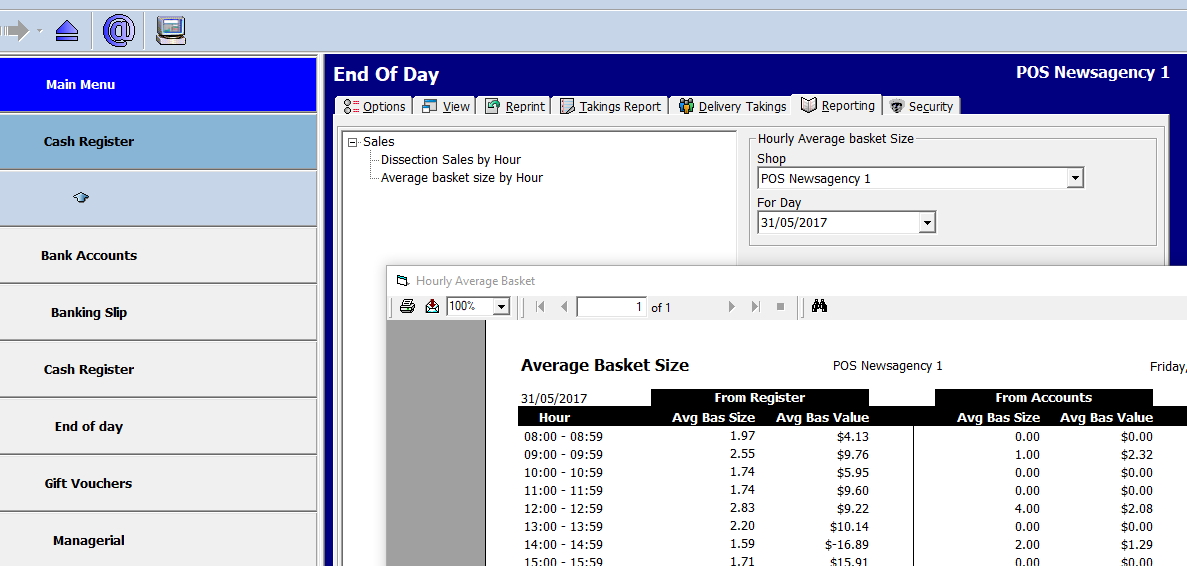

POS Solutions has long been the gold standard for Australian newsagents, offering sophisticated “state-of-the-art” automatic replenishment that outperforms basic reorder tools. While other systems might offer basic ordering, POS Solutions integrates profound industry logic with an AI that understands the unique pressures of a newsagency. In 2018, we released an automated AI ordering system because one of our programmers was very keen on neural networks. It was an incredible achievement. As such, all our clients have had it free. Since it’s actually an AI trained on our customers’ data for many years, it beats AI like ChatGPT or Gemini hands down as it was specially trained for the task. I know we have tested it. Best of all it is free

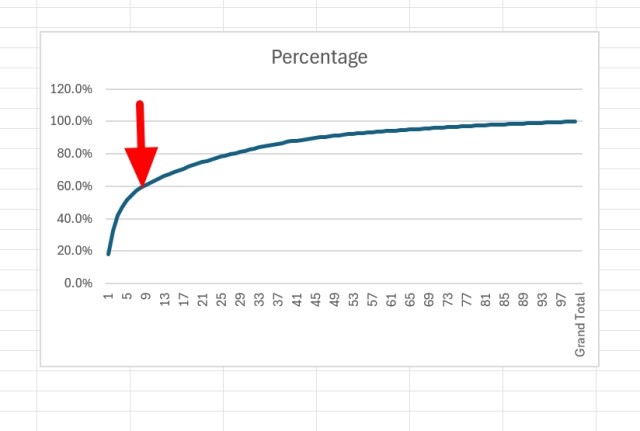

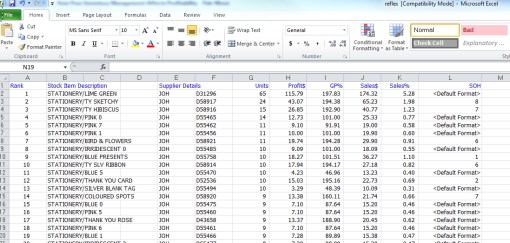

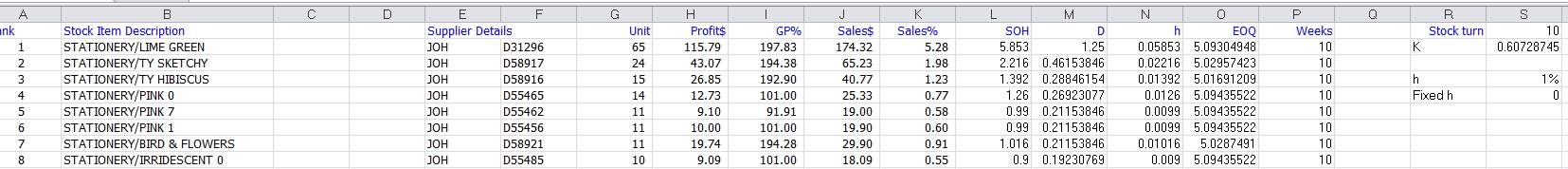

Most of the time, the system does exactly what you want. It quickly reviews sales history, stays consistent, and can create suggested orders across every stock line in your shop. That last point matters because no human has the time to carefully review every single item, every single week, without missing something. If it takes you three (3) minutes to review an order for a single item and you have a thousand items in that department, that is 3000 minutes. That is two days of work. It cannot be done by hand.

However, there’s a catch: even though the best AI is brilliant with patterns, it can be what we call “context blind”. It sees the numbers, not what you know in the story behind the numbers.

That difference matters most in a mixed business:

- Some products behave like “normal stock” (gifts, stationery, ink, snacks).

- Some products behave like “time-based stock” (magazines, part-works, some book series).

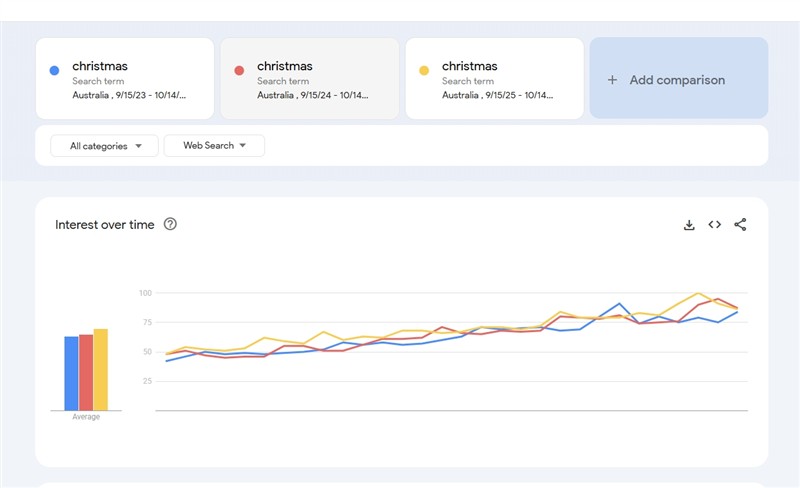

- Some products behave like “event stock” (school holidays, local events, footy finals, Christmas).

If your POS system treats every item as a standard replenishment product, it will sometimes suggest orders that are mathematically correct but don’t reflect reality on the shop floor. This is where the flexibility of our ordering system shines, as it lets you easily manage these exceptions.

What it allows you to do is buy frequently and buy small which keeps your stocks levels tight and your profits high.

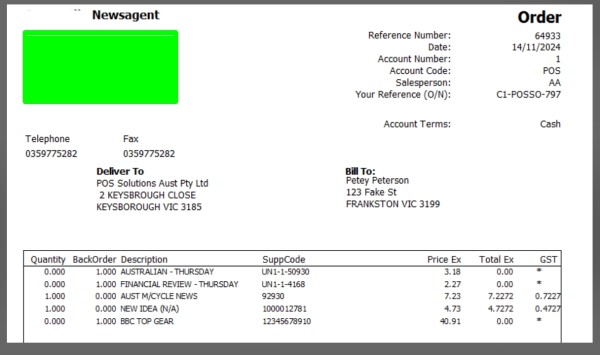

I will give three scenarios to show the issue.

Scenario 1: The one-off spike (lumpy demand)

Sales over the last 10 weeks:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Sales | 3 | 0 | 4 | 0 | 2 | 0 | 0 | 0 | 8 | 7 |

...and then you ran out.

This is a classic inventory trap. You see long periods of zero, then a sudden jump. A standard forecast (often a weighted average that favours recent weeks) can overreact and suggest a large order, because it assumes a new trend has started.

How the machine “thinks” in simple terms:

- It heavily weights the last few weeks.

- It sees

0, 8, 7and assumes demand is now “high”. - It adds extra buffer stock “just in case”.

- It lands on something like 11 units.

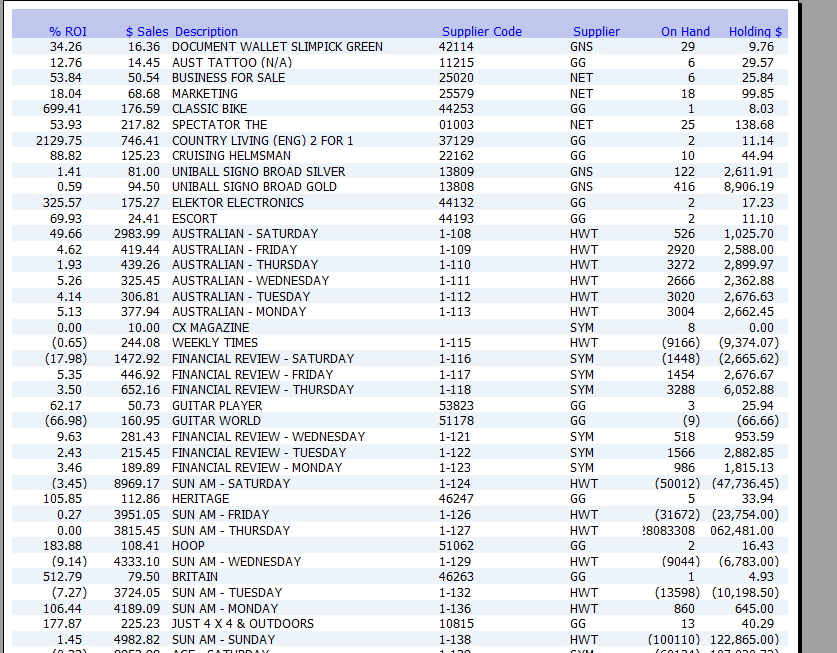

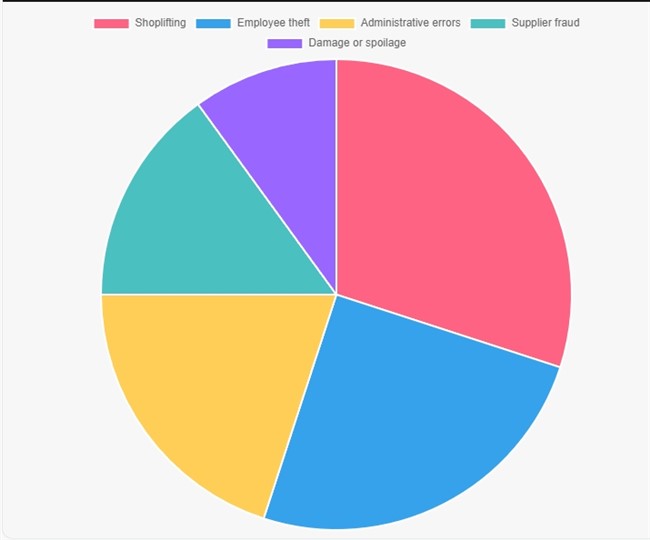

In retail, cash flow is oxygen. Dead stock quietly steals it. In fact, holding onto dead stock can cost nearly 30% more than the inventory’s value when you add up storage and insurance costs.

The better move here is to under-order and watch what happens next week. If you order 11 and the product goes back to selling 0–2 a week, you’ve tied up cash in stock that will sit there. If you order, say, 4, you can always get more if required.

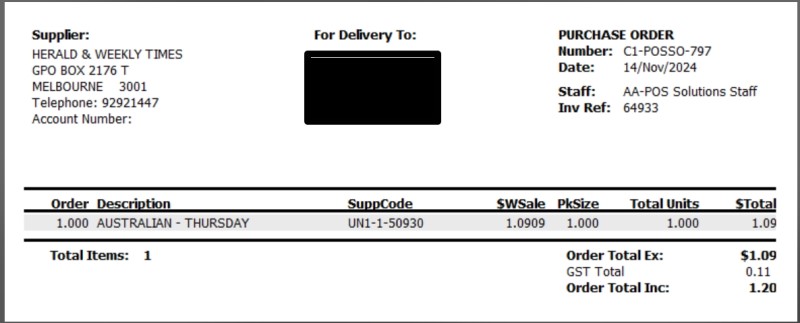

Scenario 2: Sustained growth

Sales over the past weeks:

| Week | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Sales | 3 | 3 | 4 | 3 | 2 | 1 | 5 | 3 | 8 | 7 |

...and then you ran out.

This pattern is different for one key reason: there are steady sales, and then a lift. That means the recent growth is more likely to be real.

Why the higher order can make sense here:

- Even the “older” weeks aren’t zero. The item already had a heartbeat.

- The last four weeks are much stronger than the earlier weeks.

- You ran out, which means the last number is often understated, as you might’ve sold more if you had stock.

Practical advice:

If you over-order slightly here, it’s less dangerous because the item is actually moving. Your most significant risk is under-ordering and losing sales, as in today’s market, customers won’t wait; they will go somewhere else. In a community-focused shop, that “Sorry, sold out” moment doesn’t just lose today’s sale. It can lose next week’s visit too.

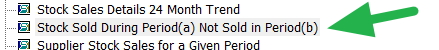

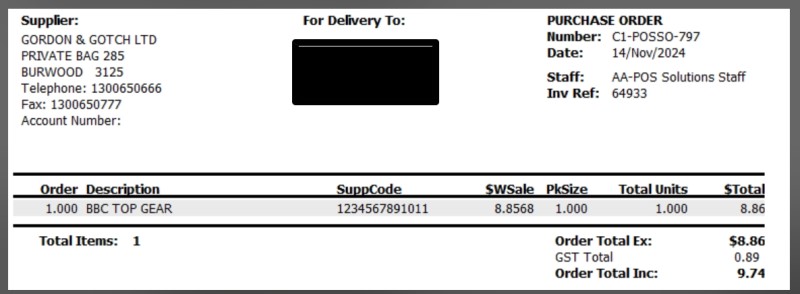

Why perishables break standard ordering logic

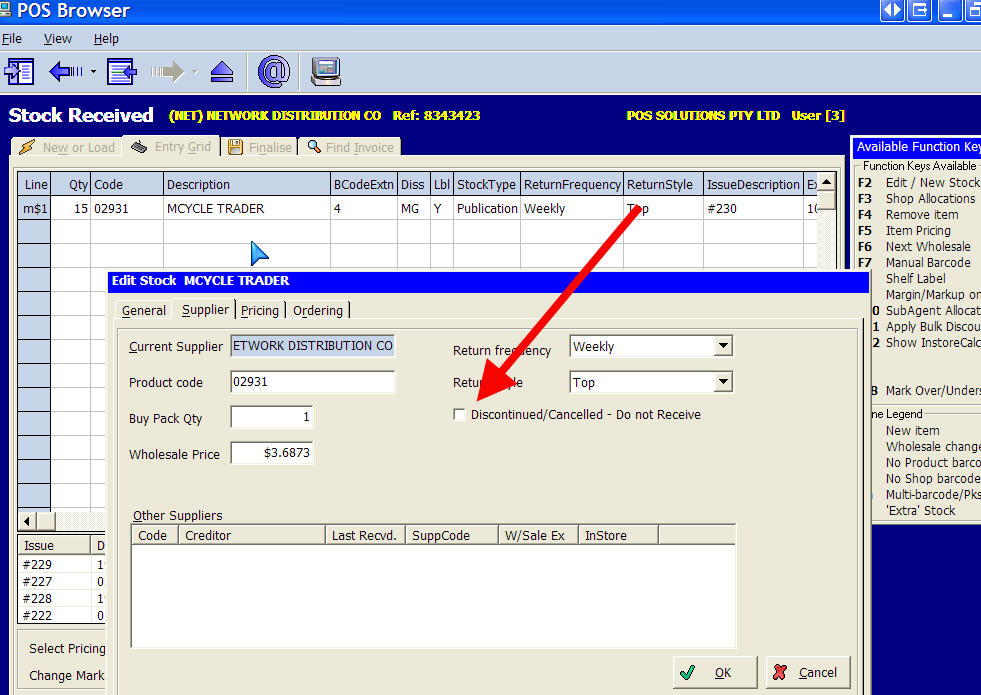

Scenario 3 highlights the problem of products that expire, e.g., magazines in newsagencies, and how specialised systems like POS software prove their worth.

Scenario 3: The monthly magazine

Sales pattern: 3, 2, 1, 0, 4, 2, 0, 0, 4, 3 and it ends in a stockout.

A generic system suggests: five units.

For many everyday products, that sounds reasonable. But here’s the problem: this isn’t a standard product. It’s a monthly magazine, a perishable, and you’re in the 3rd week of its cycle.

Fresh produce sales fade by the day. A pen doesn’t “go stale" after week one, but fresh produce does.

The best solution is to order nothing till the new product or fresh goods are available. This is where generic replenishment logic often breaks down the most. The fix is to use a system built for this exact problem. You need a system that turns off automatic orders, usually for those goods.

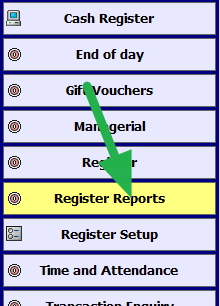

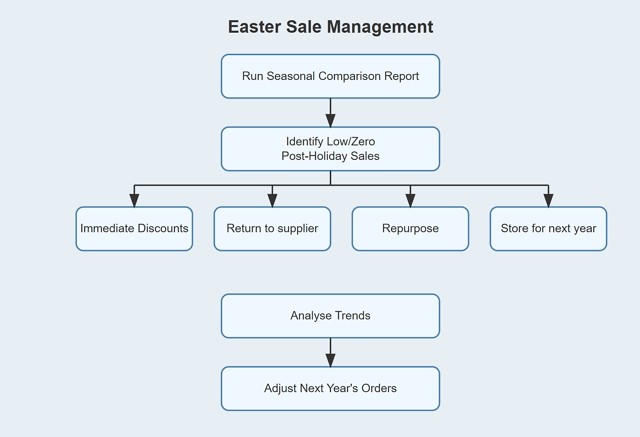

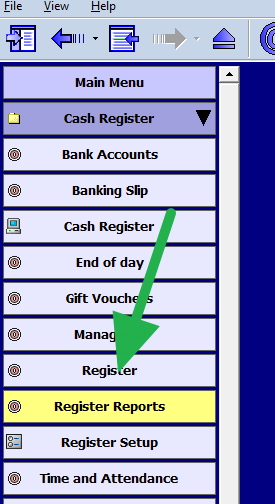

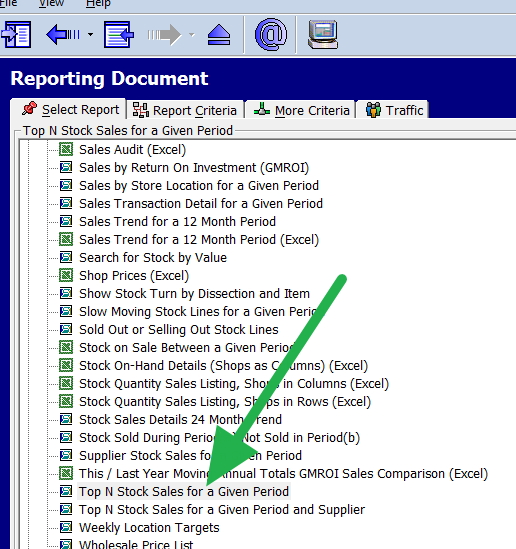

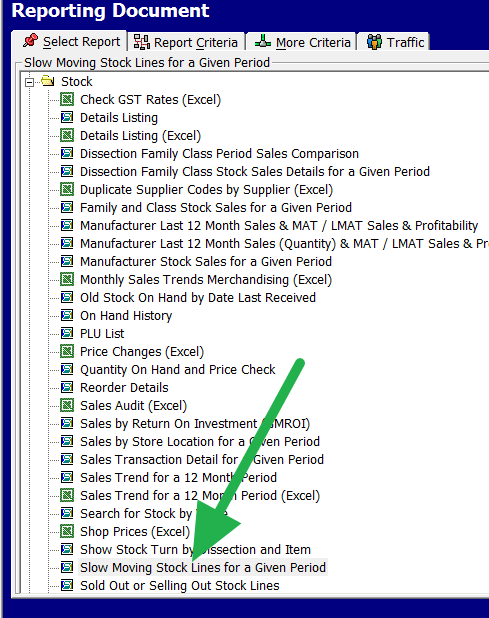

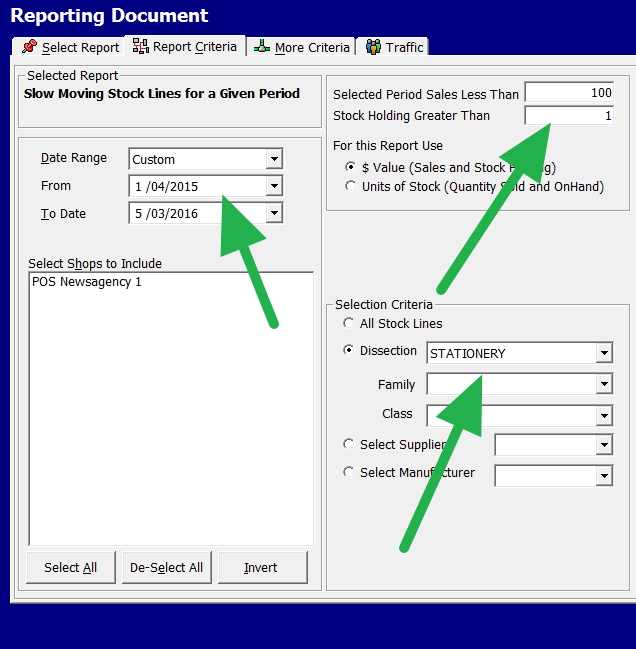

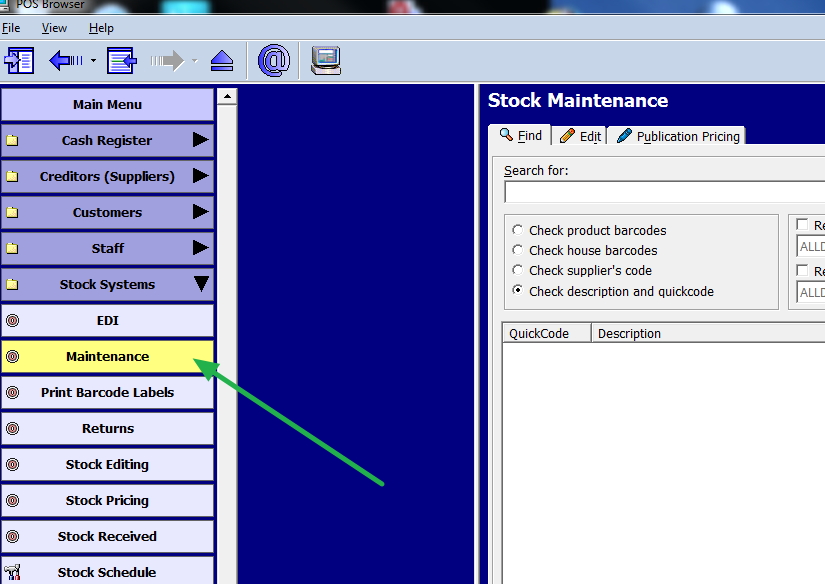

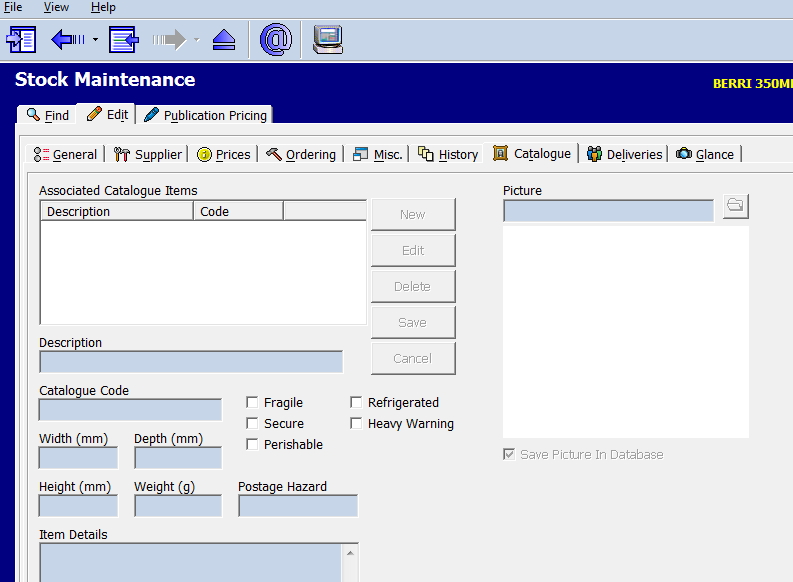

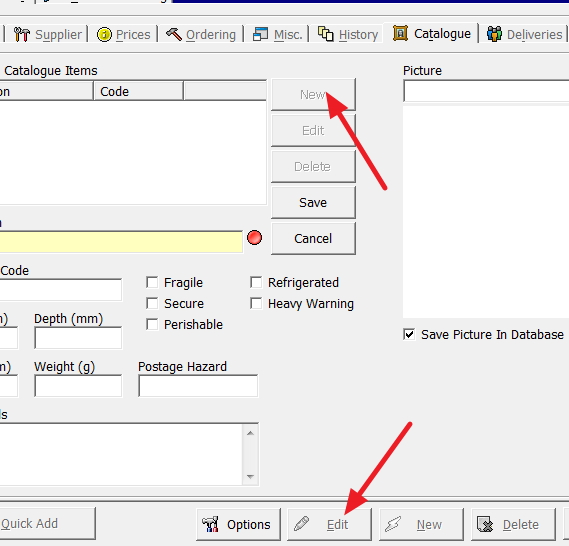

Human-in-the-Loop Workflow for Automated Ordering

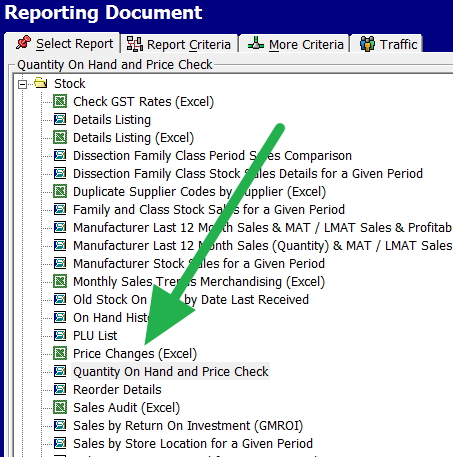

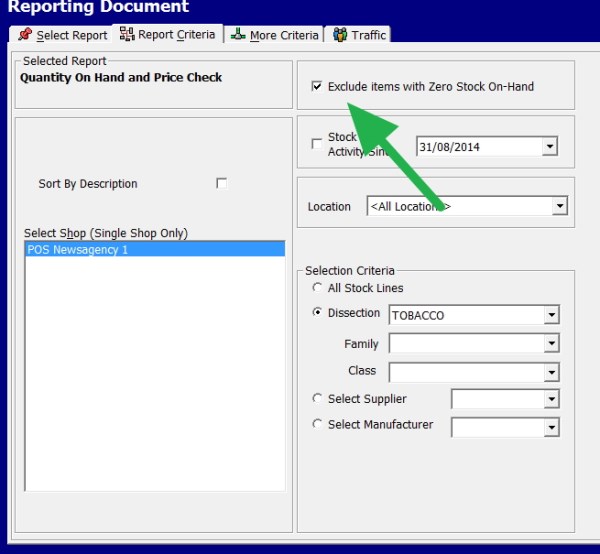

This is the part many retailers skip. They either trust the automation fully or ignore it entirely. The best results come from a repeatable review habit, using a system that makes reviews easy. Use this checklist before you action the orders.

Step 1: Classify the product

Ask: What kind of stock line is this?

- Normal replenishment (everyday items).

- Time-based release (magazines, part-works).

- Seasonal or event-driven.

- Supplier-limited or allocated.

Automation is best suited for regular replenishment lines.

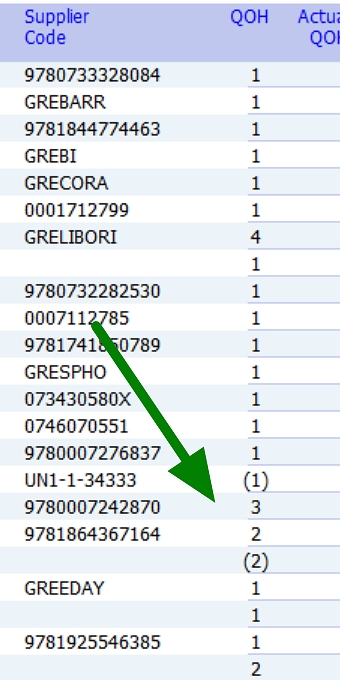

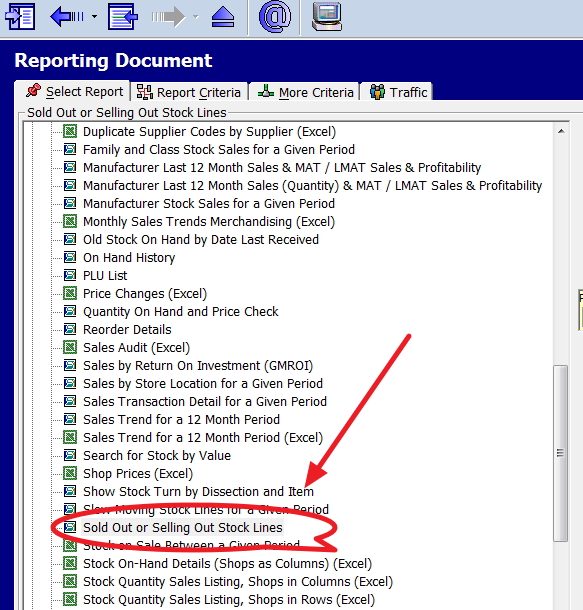

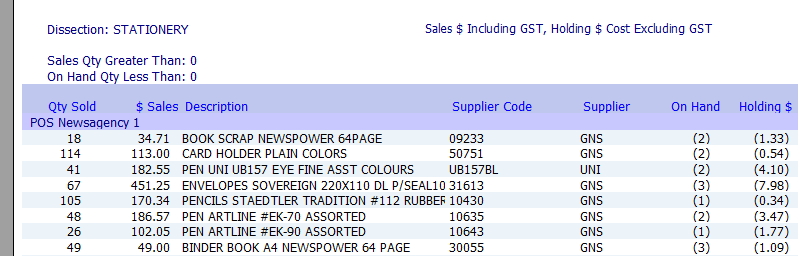

Step 2: Review stock-outs for false zero sales

A “0” in sales can mean two different things:

- No demand (nobody wanted it).

- No stock (customers wanted it, but you didn’t have it).

There is often a why behind the numbers.

Take Control of Your Ordering Today

Do not assume that a computer-generated automatic order is correct, and you cannot get rid of the human element yet. You should use the POS Software to generate a suggested order, then review it before actioning it.

Written by:

Bernard Zimmermann is the founding director of POS Solutions, a leading point-of-sale system company with 45 years of industry experience, now retired and seeking new opportunities. He consults with various organisations, from small businesses to large retailers and government institutions. Bernard is passionate about helping companies optimise their operations through innovative POS technology and enabling seamless customer experiences through effective software solutions.