Save using predictive analytics in your shop

It is not an exaggeration to say that seeing the future is a gift every business wants, but such superpowers are only in fiction. Still, the predictive technology and analytics in your POS Software will give you a better understanding of future events.

For example, using your data-driven analytics and artificial intelligence in your POS system can help you predict your ideal stock holding now based on its historical data. This can help you make real-time decisions, allowing, for example, you to overcome current delivery issues that are leading to shipping delays.

The problem is that you now have thousands of stock items in your shop. Keeping track of all these stock items is, in practice, unworkable as it is too much work. To reduce the workload, many people try to pick the top-selling items and essentially ignore the rest. It works for the top, say 100 items, but leaves the rest out of control. But it is no problem for the computer to control thousands of items.

So stop guessing, use your POS System. Users of our POS System have a free AI system years ahead of any other POS Software I know of that can predict future sales, a challenge every retail business faces. Although precise foresight remains fictional, modern Point of Sale (POS) systems with predictive analytics provide a close second. This technology analyses your past sales data to deliver highly accurate demand forecasts, enabling you to optimise stock levels, boost profitability, and make smarter purchasing choices.

The High Cost of Inaccurate Inventory

Ineffective inventory management directly impacts profitability. The most visible consequences are stockouts and overstocking, which contribute to a global problem for retailers. Inventory distortion, which includes both overstocks and stockouts, was projected to cost retailers almost $1.8 trillion in 2023. Stockouts alone account for nearly $1 trillion in lost sales for retailers worldwide each year, as customers who cannot find the product they want will often take their business elsewhere. Research shows that retailers lose nearly half of all intended purchases when a product is unavailable. These lost sales represent a significant revenue loss and can damage brand reputation and customer loyalty over the long term. Furthermore, many businesses resort to costly emergency measures such as expedited shipping and overtime labour to manage stock shortfalls, which erode financial stability.

From Guesswork to Growth: How Predictive Analytics Works

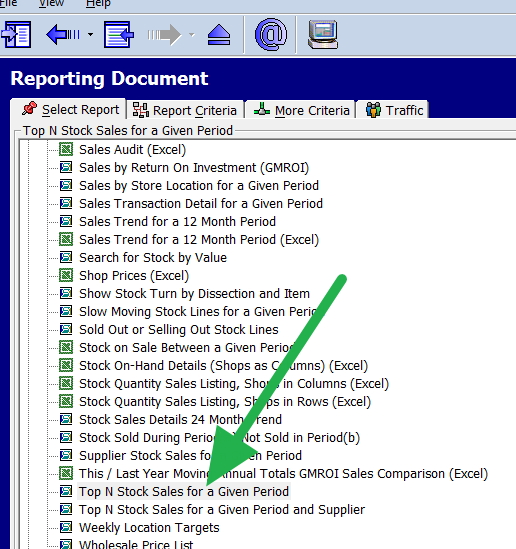

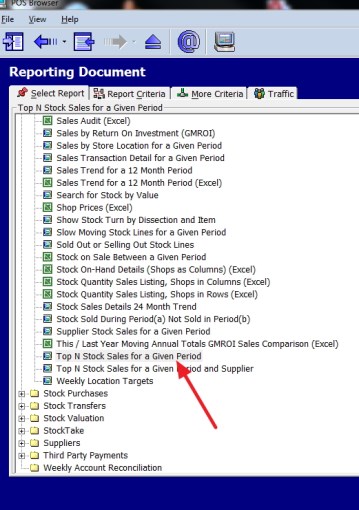

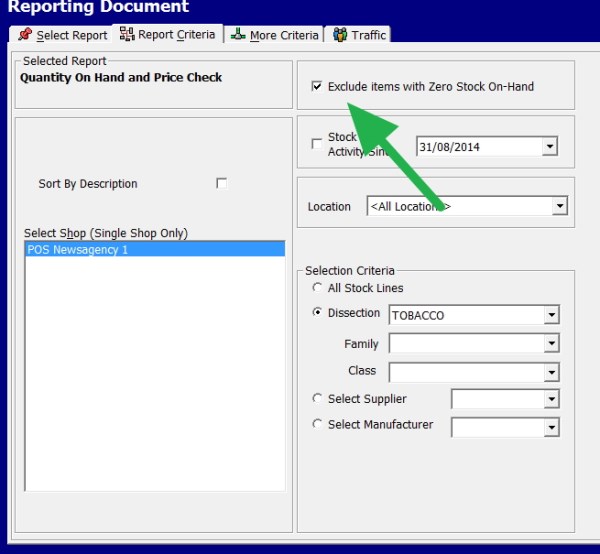

Manually tracking thousands of individual stock items is an unworkable and inefficient task that often leads to errors. Many retailers attempt to manage this by focusing only on their top-selling products, leaving the majority of their inventory unmanaged and susceptible to costly stockouts or overstocking. Predictive analytics integrated within a POS system automates this entire process, providing a comprehensive solution.

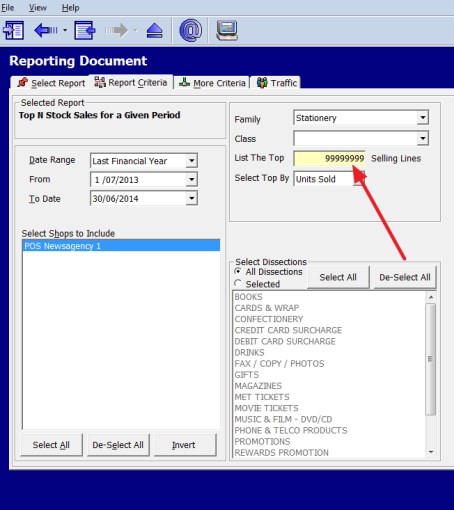

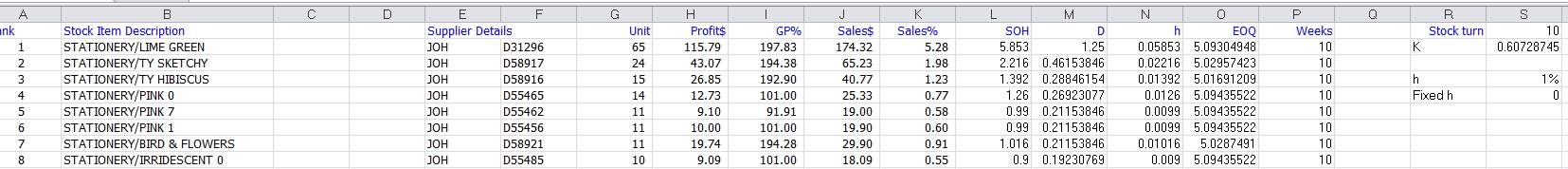

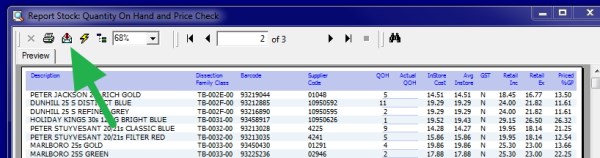

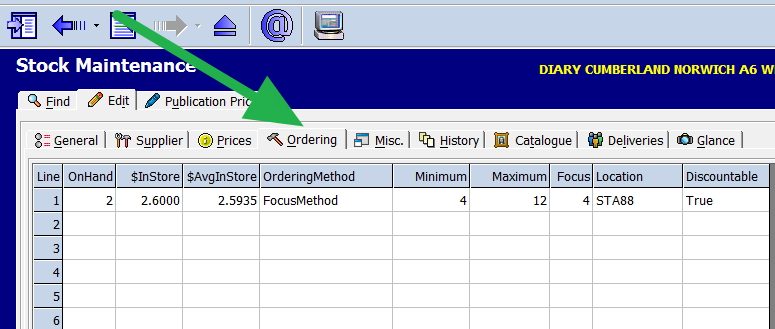

The system’s artificial intelligence uses historical data to forecast ideal stock levels for every single item. This enables data-driven, real-time purchasing decisions that can mitigate challenges such as shipping delays. For instance, consider a scenario where your system flags a specific item for review. The data might show you have only two units on hand, but the predictive analytics, based on recent sales velocity and seasonal trends, forecasts four sales for the upcoming week. The system immediately recommends a reorder, allowing you to prevent missed sales and ensure customer satisfaction.

Measurable Business Outcomes and ROI

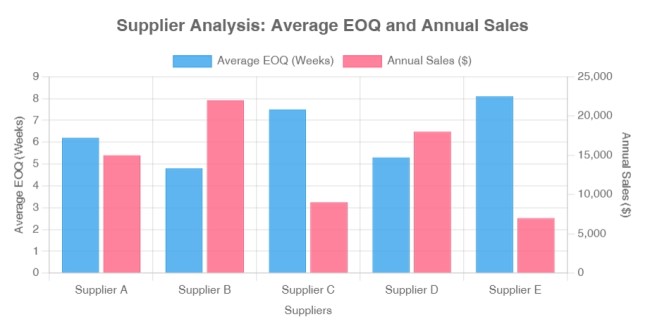

The implementation of predictive analytics delivers tangible returns by converting data into strategic assets. By ensuring popular items are consistently available, you not only capture immediate sales but also strengthen customer loyalty and satisfaction. One of our clients, a mid-sized retail business, discovered an unforeseen surge in demand for a niche product line through their POS system's analytics. By flagging the initial sales trend, the system enabled them to adjust their ordering strategy promptly, capturing significant sales that would have otherwise been lost.

Moreover, this technology greatly cuts the financial cost of overstocking, freeing up capital that would otherwise be tied up in unsold goods. Case studies have demonstrated that businesses using real-time inventory tracking and predictive analytics can boost revenue by 12% and cut emergency replenishment costs by 30% within 6 months. By automating replenishment, organisations can cut stockouts by up to 40%, directly increasing profits and encouraging sustainable growth.

Conclusion

Shifting to a proactive, data-driven strategy is essential for growth.

Ready to stop guessing and start selling smarter?

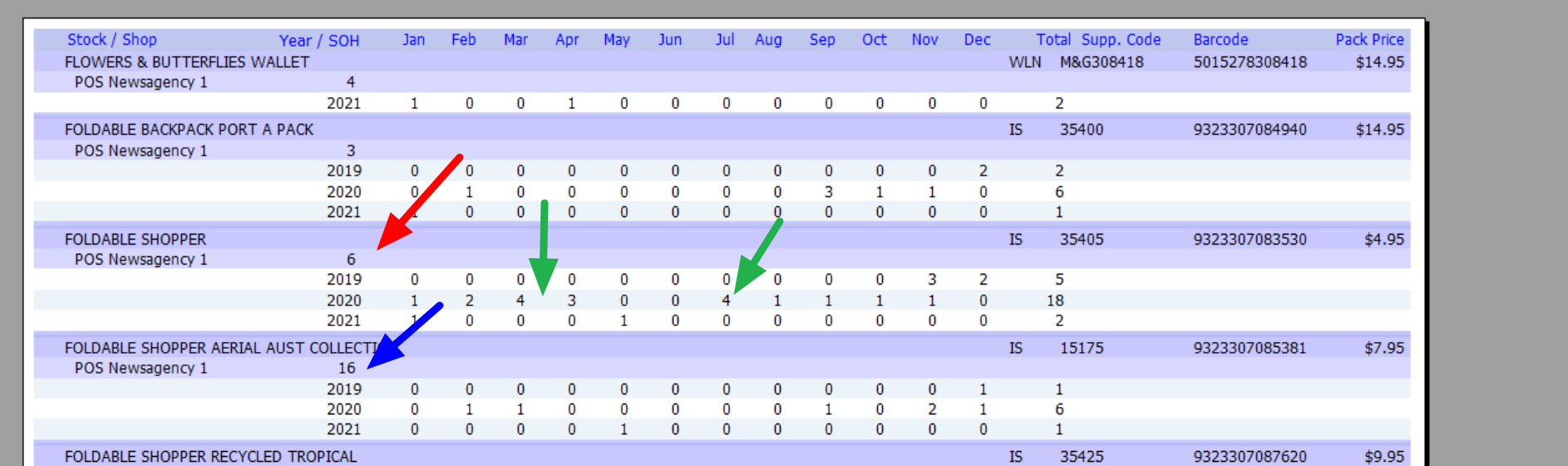

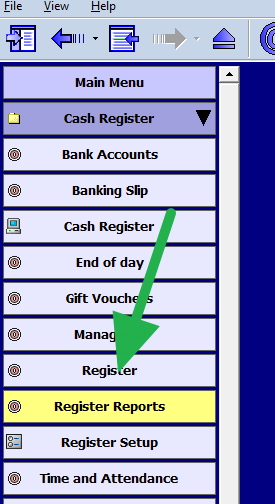

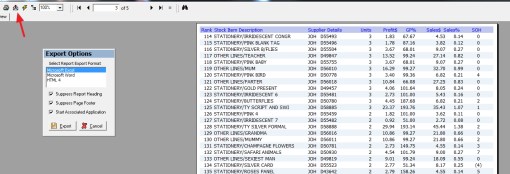

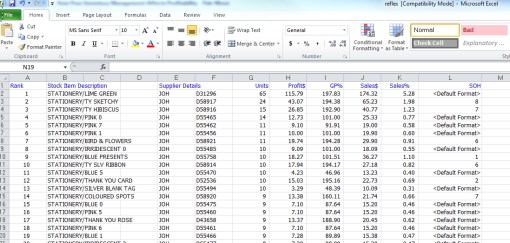

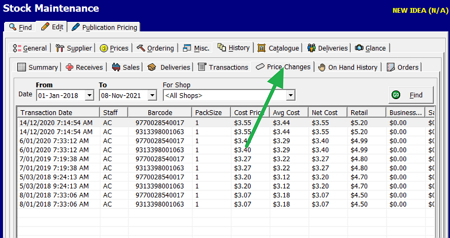

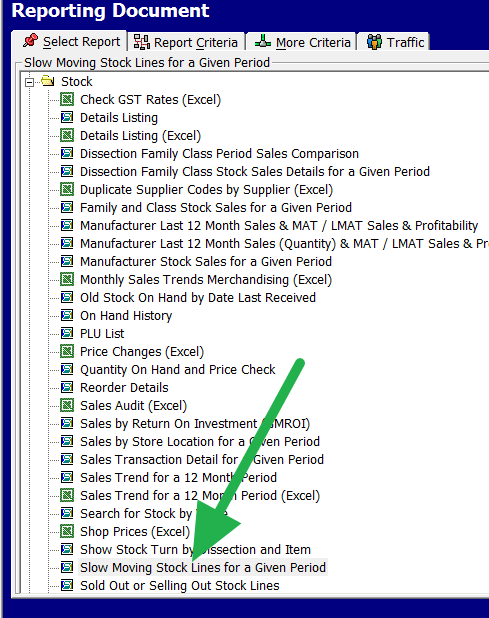

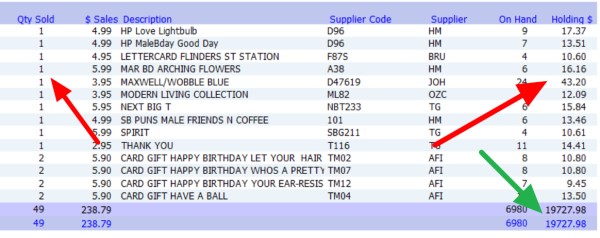

Let me show you an example. See the example of a stock item above in the ordering screen.

We have here two (2) on hand. The expected sales for this week (focus quantity) are four (4) sales a week. So the computer is saying you need to order ASAP or miss out on sales this week and a few next week until you get it in stock.

That is one item. You now have thousands of stock items in your shop. Doing this is too much work manually.

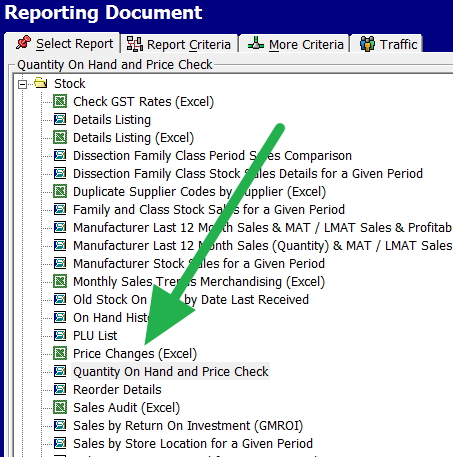

Using it, you can spot early warning signs.

One of my clients recently discovered that he had forgotten about Diya lamps. These surged in sales last month, so okay, he missed some but managed to get much of it. So he got some excellent sales that he would have missed out on without this predictive analytics.

If you need any help or want to get an automated stock control system going in your shop, please get in touch with us.

Written by:

Bernard Zimmermann is the founding director of POS Solutions, a leading point-of-sale system company with 45 years of industry experience, now retired and seeking new opportunities. He consults with various organisations, from small businesses to large retailers and government institutions. Bernard is passionate about helping companies optimise their operations through innovative POS technology and enabling seamless customer experiences through effective software solutions.