I was reading an article by a marketing professor from Emory University, Sundar Bharadwaj, where he did a huge study of 71,000 customers to learn how they reacted to the retailer not having stock of the item they wanted.

He found the following overall.

- 9% did not purchase the item

- 15% came back later to buy the item

- 45% brought something else

- 31% went to another store.

Overall, the retailer lost nearly 40% of the sales on that item.

It would be worse as what does the customer who goes to another store do on their customer loyalty on their next shopping trip.

Typically, the study stated that the sales loss to a shop was about 4% of turnover.

However, this part was the most interesting, what did they find was the main cause of these out of stock situations, 72% of the time it was the retailer fault?!

While you cannot order limitless quantities, ordering frequently can help.

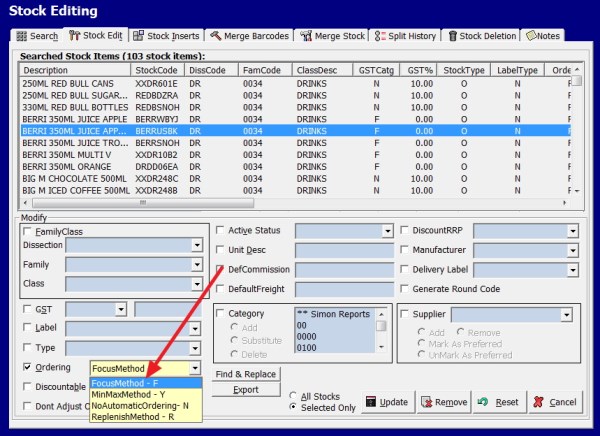

For slow moving items, we recommend using focus ordering, which is available in our system. It is a form of "just in time" method of stock control and allows you to plan how much stock you should have now. Here is how you set it up for these items.

Once set up the computer tracks the stock on hand, estimates the stock level required for these goods in the period (focus), if it thinks that the stock on hand is too low it can send an order to a supplier with the speed and accuracy that no-one can match.

It is easy to set up, and use for details click here.

With effective software, you can control your stock better.

For details on how to do this, please, click here

Reducing out of stock can take a while to set up, it can be difficult, time-consuming and labour expensive but the cost of assuming it does not really matter may be higher still in a business that we tend to service that have perilously thin margins.