Managing your inventory is crucial. Carrying too much Dead Stock (items that never or rarely sell) can drain your cash flow and waste valuable storage space that could be used for products customers actually buy.

Deadstock, you may know as your Shelf-sitters, Dust collectors, Deadweight inventory and Stagnant inventory, it's all the same thing. It's stock that is sitting in the shop and does not sell.

That is why we all try to streamline our inventory. However, a better solution is not to get the Dead Stock in the first place.

Fortunately, your point-of-sale (POS) software likely has built-in features to help you identify and mark Dead Stock.

Dead Stock

Your POS software has robust reporting capabilities. Use them to pinpoint:

- Seasonal items that didn't sell. Those Santa hats were a great idea in August, but they're irrelevant now.

- Slow sellers. Flag items that have been sitting on shelves for months or years without selling. They're taking up space that sellers could occupy.

- Damaged/defective goods. These need to be addressed.

- Obsolete inventory. For these you need some intelligence because the computer does not know the latest fads. Books on Oppenheimer sold well while the movie was hot but now they soon will be outdated and occupying space.

Click here for more details.

Use "Do Not Order" Features

In your POS Software, you can mark an item so that others do not accidentally order it and that if it does come, it will be marked on the computer as not wanted. It's a common problem in retail, for example, in my grandfather's shop. I remember as a kid how happy he was that we finally cleared some items, only to discover a short time later, to his horror, that my Mum, noticing we were out of it, had put in a fresh order, and it was back. This is how you can stop it.

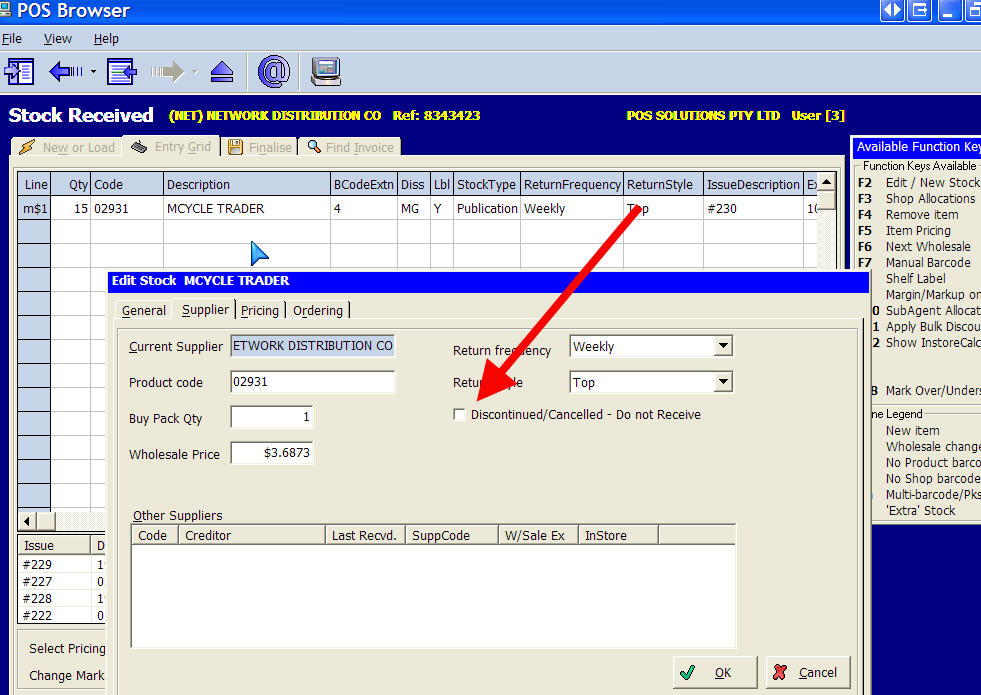

We call this "Do not receive." You can either do it in stock maintenance or in-stock received.

For example, while receiving, go to edit. Mark the item where the red arrow is. From then on, in your POS system, it will show it as NOT WANTED, and if it does come in, the point-of-sale software will put it on the list to be instantly returned.

This avoids wasting money re-ordering a product that doesn't sell.

Benefits of Managing Unwanted Inventory

Taking control of obsolete and slow-moving stock has many advantages:

- Saves money otherwise spent on storing and managing unwanted products

- Frees up inventory space for faster-moving products

- Allows you to focus purchasing on your bestsellers

- Reduces wasted time counting and accounting for products you don't want

- Ensures you have the right mix of products to meet customer demand

- It frees up cash flow sitting in dead stock.

The bottom line? Don't let unwanted inventory eat into your profits and operations. Use your POS system tools to take back control!